To say Sony has been on a roll with their camera sensors is to say that that PS4 has been a modest success for the company. Already this year, we’re seeing the company flex their expertise by introducing slow-motion video on their upcoming Xperia XZ Premium at 960fps and their IMX390 sensor which was developed with self-driving cars in mind. Now, Sony has another sensor to introduce to the world: the IMX382. As PetaPixel points out, the IMX382 is

an industrial sensor that can recognize and track objects at an insane 1,000fps.

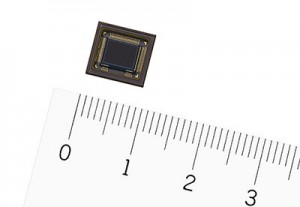

The newly announced IMX382 is not destined to wind up in your smartphone, point and shoot, or ILC… it’s too small. At just 1.27MP, it was designed specifically for industrial use in factories, where it’ll spot issues with assembly line products more efficiently than anything else out there.

That’s because Sony built circuitry right into the sensor stack that can recognize and track moving objects accurately at 1,000fps

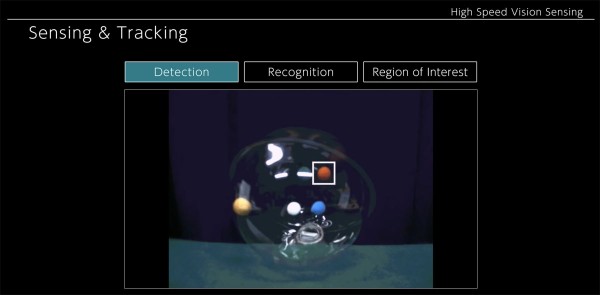

Here’s a video of the sensor in action:

At just 1-megapixel, this tech is obviously not meant for typical cameras and smartphones, or at least certainly not yet. But in the context of the above video, it’s easy to see how this sort of technology can be what propels Sony forward. The IMX390 is already hugely important as we enter the age of autonomous vehicles which will eventually make up the entirety of vehicles on the road; from buses to trucks, vans, and even sports cars. Even semiautonomous cars will require sensors and that’s a market that Sony can dominate from its inception.

Automized factories of course are nothing new but as the pace that AI and robotics advances, we’re likely to see an even greater increase of manufacturing jobs disappear. The politics of that aside, in order for these factories to run at maximum efficiency, they’ll need to be as self-contained as possible and the IMX382 sensor will most certainly play a role in that. Outside of factories, it’s easy to see this sensor being incorporated in other avenues like vending machines, city lights, grid systems, and more where the key isn’t the visual quality, but the tracking.

PlayStation aside, Sony has struggled to find a hit consumer product in well over a decade but perhaps that’s not where their future lies and instead, it’s their sensor business that will propel them forward as our ever digital world continues to becomes more connected. In order for the future world of Star Trek to come to life, we need sensors and machine learning in every product that we come in contact with but a blind device can only extrapolate so much data from its surroundings. Could it be that it’s Sony who helps bring vision to AI?

From Sony:

From Sony:

Tokyo, Japan—Sony Corporation today announced the release of the new IMX382 high-speed vision sensor, which enables detection and tracking of objects at 1,000 frames per second. Sony will begin shipping samples in October 2017.

This vision sensor features a stacked configuration with a back-illuminated pixel array and signal processing circuit layer. The circuit layer is equipped with image processing circuits and a programmable column-parallel processor, delivering high-speed target detection and tracking. This configuration enables high-sensitivity imaging thanks to the back-illuminated pixel array, with target detection and tracking at 1,000 frames per second. The new sensor uses information such as color and brightness obtained from pixels to detect objects, then extracts the object’s centroid, moment and motion vector, and finally outputs the information from the vision sensor in each frame.

This vision sensor has achieved imaging, target detection and tracking at 1,000 fps on a single chip. This not only expands the scope of application, but delivers new value that was difficult to obtain with conventional systems.On past systems equipped with a 30 fps processing image sensor, it was not always possible to capture fast-moving objects and/or phenomena. At 1,000 fps, approximately 33 times faster in imaging speed than conventional chips, the new product can capture fast-moving objects and detect objects from image information, while using high-speed processing to extract information such as centroid, moment, and motion vector. Because the processing results can be output from the sensor in each frame, feedback to the system is faster than conventional methods. Delays in detecting anomalies or malfunctions in production lines at factories and other places can produce fatal results. However, this vision sensor makes it possible to instantly capture such events, so that orders can be issued quickly to stop the system.Conventional industrial robots are normally operated by specifying motion coordinates using a program. Utilizing the high-speed tracking functionality of this vision sensor, however, enables real-time feedback to robots, enabling autonomous robot operation that is responsive to the movement and status of objects. This helps make robot teaching more efficient, contributing to improved productivity.

On conventional systems, the image processing required for detecting and tracking of objects has to be carried out at a later stage (on a computer, or other computing device). This vision sensor changes all that by delivering imaging, target detection and tracking image processing on a single chip. Not only does this make the later stage devices more compact and help to save overall system power; it also expands the new system development potential by eliminating certain physical limitations.

Timed with the sample shipping, Sony will also be providing evaluation kits. The evaluation kit consists of the camera and control software, making it easy to evaluate the sensor in diverse customer environments.

Sony is focusing intently on the sensing field and seeking to leverage its potential in the image sensor market. By integrating the imaging technology that it has developed over the years with sensing technologies that enable information acquisition and utilization, Sony strives to pioneer new applications and new markets for image sensors.

Main Features

- 1. Enables detection and tracking of targets at 1,000 frame per second

- The signal processing circuit layer on the bottom of the stacked configuration is equipped with image processing circuits and a programmable column-parallel processor, delivering high-speed target detection and tracking. This construction enables high-sensitivity imaging with back-illuminated pixel array and achieves target detection and tracking at 1,000 frames per second.

- The new sensor uses information such as color and brightness obtained from pixels to detect objects, then extracts the object’s centroid, moment and motion vector, and finally outputs the information from the vision sensor as a signal in each frame.

- 2. Built-in sensing function for a compact system and power savings

- The product achieves imaging and image processing on a single chip. Not only does this make for a more compact overall system and power savings; it also expands the new system development potential by eliminating certain physical limitations.

- For system output, in addition to the image data output pathway the chip is also equipped with an output pathway solely for sensing information, so users can select between them for their particular application.

- 3. Evaluation kit allows the sensor to be evaluated in diverse usage environments

- The evaluation kit consists of a camera and software and is designed makes it easy to evaluate the sensor in a variety of customer usage environments.

Who knows, maybe I have my optimist hat on today but I can’t help but be bullish about Sony’s future with innovations like this which will be invisible to most consumers, yet have a profound impact on their daily lives.

You must be logged in to post a comment.